Robust, high performance; our packers are designed to handle high differential pressures in single or multiple zones application, whether vertical or highly deviated wells. Built according to the client’s needs, with materials that allow the greatest possible reliability and durability.

Completion and sand control

- Navegando en

- Completion and sand control

PERMANENT PRODUCTION PACKERS

ACCESORIES

The mechanical latch sub, has a ratchet latch type threads. The tool is installed inside the hydraulic packers which have a compatible threads that are easily connected by loading the weight; it is basically an extension, to thread in the production pipe. Releasing it from the packer only requires turning the production string about 10 turns clockwise while applying 500 to 1000 lb of tension above the weight of the tubing.

It is used below the production packer, in order to provide a seal to test the integrity of the string. It features a tapered end that allows wireline tools to re-enter the well with no issues. The re-entry guide with blind ejectable plug is suitable for Wells with high angle, the interior of the TP should be filled with fluid to avoid high differential pressures.

The rotational expansion joint compensates for tubing movement during production closure or well stimulation in single strings completion. Its design allows the pipe to transmit the torque though its entire run length. The seal integrity is maintained by a premium elastomeric and non elastomeric seal system.

FLOW CONTROL TOOLS

Designed to be installed below the selective series seating nipples, or at the bottom of the completion string, to provide a specific location for Surface flow equipment. The internal profile of these nipples include a slight no-go restriction which prevents slickline tools from being run underneath and thus avoid eventual loss of the them.

HERRAMIENTAS DE SERVICIO

The Retrievable Bridge Plug is a high pressure plug used for multi-zone treatment and injection, stimulation operations. The bridge plug is designed to be anchored in both tension or compression operations, making it ideal in shallow applications, to checkheads or inspect the well casing, and in deep applications, for temporary well abandonment, securing the well or performing stimulations.

The test packer is a recoverable compression packer designed for general service purposes, which can withstand differential pressures coming from below or above, it is anchored with a quarter turn, followed by downward weight loading. This can be run with a mechanical bridge plug to test different intervals or it can serve multiple purposes in a single run.

GAS LIFT

The GLMGA-1.5SL pocket chucks are provided with an oval body design with threaded connections for installation in the Production Tubing (TP) string. This pocket is eccentric to the hole of the TP, thus allowing a complete passage through the pipe, through the mandrel, without restrictions, in order to perform well service operations. This said pocket is provided with a profile and a polished section which allow to house the pneumatic pumping valves as well as other flow control equipment.

The model JM20R gas lift valve is a slickline retrievable valve designed for continuous use in gas lift applications, when installed on an M series mandrel, the valve is used to control the flow of gas from the casing into the pipeline. When installed on an M series mandrel, the valve controls the flow of gas from the production line to the casing.

The model RK upper latch is designed to be installed on the gas lift valve and other accessories for the pocket chuck, it uses a seal ring which is held in position by a spring. When the padlock enters the pocket of the chuck the seal ring moves upwards, when the “latch” settles, the ring is positioned in the seal recess of the pocket, to recover it, an internal pin breaks with tension force , allowing movement up and out of the seal ring mandrel.

SAND CONTROL

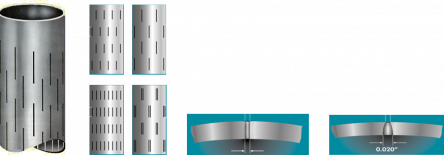

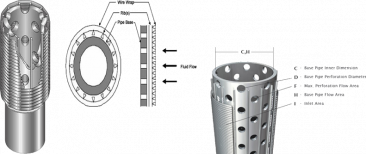

Real+ is a stainless steel wound wire filter element, with a superior manufacturing process, which allows to maximize the open flow area while maintaining strict gauge control, even in slot sizes as small as 0.003 ”(75 microns) . Its large flow area allows higher production rates with low flow rates and minimal pressure drop compared to other sand control devices. The slot opening remains unchanged even under the toughest handling and production conditions.